Comsol Multiphysics and Comsol Server updated

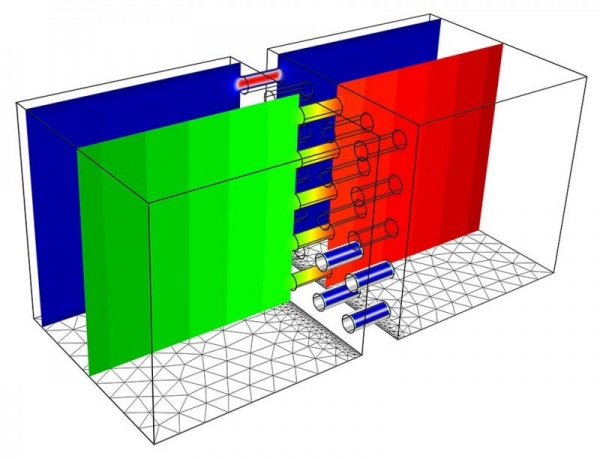

Comsol, the leading provider of multiphysics modeling, simulation, and application design software, today announced the latest release of the Comsol Multiphysics® and Comsol Server™ simulation software environment. Hundreds of user-driven features and enhancements to Comsol Multiphysics®, Comsol Server™, and add-on products have been implemented with an emphasis on accuracy, usability, and productivity. From new solvers and methods, to application design and deployment tools, Comsol® software version 5.2a expands the electrical, mechanical, fluid, and chemical design and optimization capabilities.

In Comsol Multiphysics 5.2a, three new solvers deliver faster and more memory efficient computations. The smoothed aggregation algebraic multigrid (SA-AMG) solver has proven to be particularly efficient for linear elastic analysis, but is also applicable to many other types of analyses. The domain decomposition solver has been optimized for handling large multiphysics