Best-sellers and newcomers: Film coaters, blenders and the B

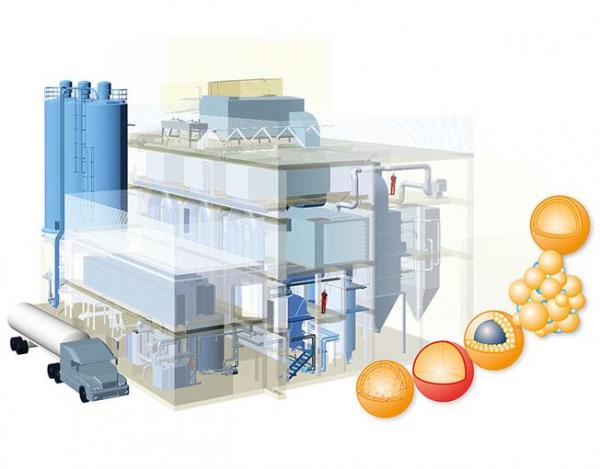

Bohle with broad range of products Frankfurt/Ennigerloh, June 2015. At ACHEMA, L.B. Bohle presents its extensive range of products for pharmaceutical solids production. In addition to the innovations, the focus will be on best-sellers such as the process and laboratory machines for batch production, such as coaters, granulators and blenders.

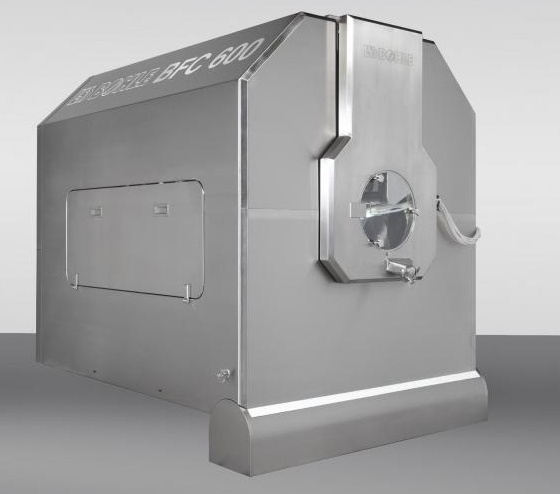

In the field of coaters, Bohle testifies to its technological edge with the Film Coater BFC 200. ”With the BFC, the visitors can experience the many benefits of the high-end version of the coater series, which achieves 40 percent higher performance levels than traditional coaters,” explained Sales Manager Tim Remmert. Moreover, the BFC 5 laboratory machine is presented in Frankfurt.

With is dry and wet granulation technologies, L.B. Bohle lives up to its name as the provider with the greatest range of granulation solutions. The VMA Vagumator®, which will be presented to the public in Frankfurt, is based on the single-pot-technology. Blending, granulating