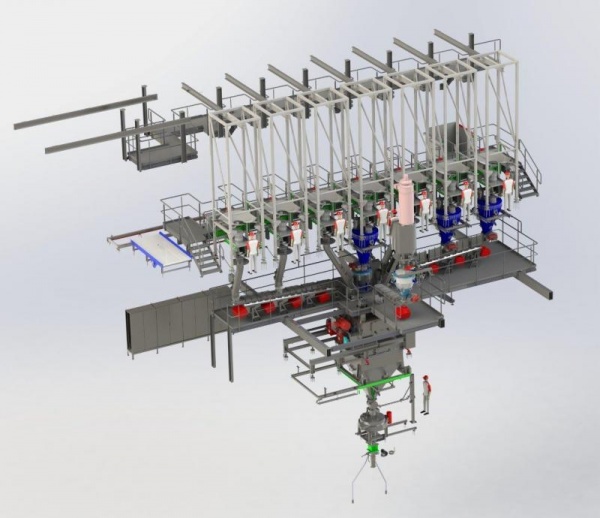

Dima 1200 bag emptier with integrated automated pallet handl

Dinnissen Process Technology has developed a new bag emptier with an integrated automated pallet handler especially for companies looking to process large numbers of bags. This latest version of the popular Dima 1200 can empty between 200 and 1500 bags per hour quickly, safely and efficiently. In addition, it helps companies to comply with stricter standards of hygiene and to minimize product spillage/waste in a wide range of industries.

Emptying a large number of bags with various ingredients in the feed, food, pharma and chemical industries is a labour-intensive, unsafe and expensive activity. In response to the needs of such clients, Dinnissen developed the new Dima 1200 bag emptier with integrated automated pallet handler. With this fully automated facility, a forklift operator can empty between 200 and 1500 bags, (i.e. 200 kg to 50 tons, per hour). All the operator has to do is to feed the pallets with the bags into the facility. The pallets are first tipped