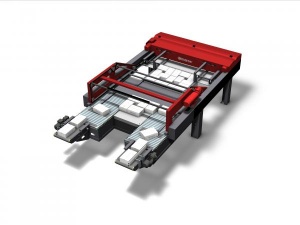

A more efficient way to stacking accuracy and stability

BEUMER gives its high-capacity layer palletiser a complete overhaul BEUMER has fundamentally reengineered its high-capacity layer palletiser BEUMER paletpac. The user now benefits from better accessibility, shorter assembly period, higher flexibility and, as a result, from lower costs. The system supplier thus continues to pursue the ambitious goal of offering its customers solutions that are sustainable in every respect. The BEUMER paletpac is incorporated into high-performance packaging lines to process highly sensitive and valuable products in a gentle and efficient manner.

With the layer palletiser series BEUMER paletpac, BEUMER supplies high-capacity machines, which stack bags filled with bulk material on pallets gently and exactly, layer by layer. The products include cement, mortar, pellets, industrial salts and fertilisers filled in paper, polyethylene or polypropylene bags. Owing to the geometric precision during layer and stack formation, stable bag stacks are formed. Multiple pallet loads created with the BEUMER paletpac