HOSOKAWA big bag emptying stations: Completely clean

Emptying big bags without contaminating products in the food industry.

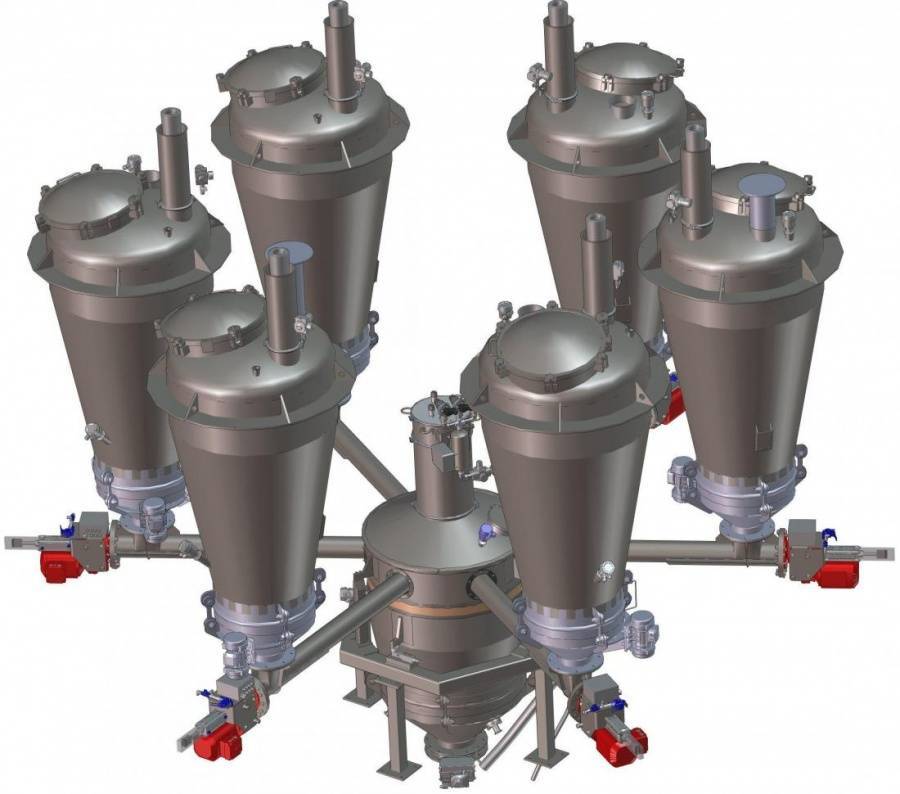

Especially in the food industry, the requirements for complete emptying and contamination-free production are very high. This is guaranteed by the soldis big bag emptying station from HOSOKAWA Solids Solutions GmbH in Landsberg am Lech.

Projects for customers in the food industry often involve emptying powdery to granular bulk materials from big bags.

Different bulk materials are delivered in bags. The main task is to empty the various bulk materials with different product or flow properties in a dosed manner without cross-contamination when changing products. This is an important basic requirement to ensure the quality of the subsequent processes and the quality of the end product.

The big bags are made available via an integrated crane system, after which the discharge hose is connected dust-tight to the docking unit of the emptying station. Containers with different dimensions can be emptied by quickly changing the moulded parts on the docking unit. Dust generated during the big bag change or during the emptying process is extracted via an aspiration system so that neither the operating personnel nor the environment are exposed.

To ensure easy cleaning after the product change, the components that come into contact with the product are easily accessible and easy to dismantle. The advantage here is the solids rotary valve with pull-out rotary valve, which is easy to dismantle and clean.

To enable simple handling of the project, the entire responsibility from planning, production, delivery, commissioning with operator training to the final handover of the system lies in one hand. Future service and maintenance tasks can also be taken over by HOSOKAWA Solids Solutions GmbH - the supplier of the entire system. As the complete delivery and service programme comes from a single source, problem-free project handling can be ensured.

Investing in a solids big bag emptying station, which is available in various sizes, offers the customer many advantages. Whilst cleaning time is reduced, system availability can be increased at the same time as product quality is improved. Thanks to a sophisticated system concept, operational safety is increased, clean dust-free operation is ensured and the requirements of ATEX 2014/34/EU are successfully implemented.

We are exhibiting at Anuga FoodTec 2024, visit us in hall 10.1, stand D-061