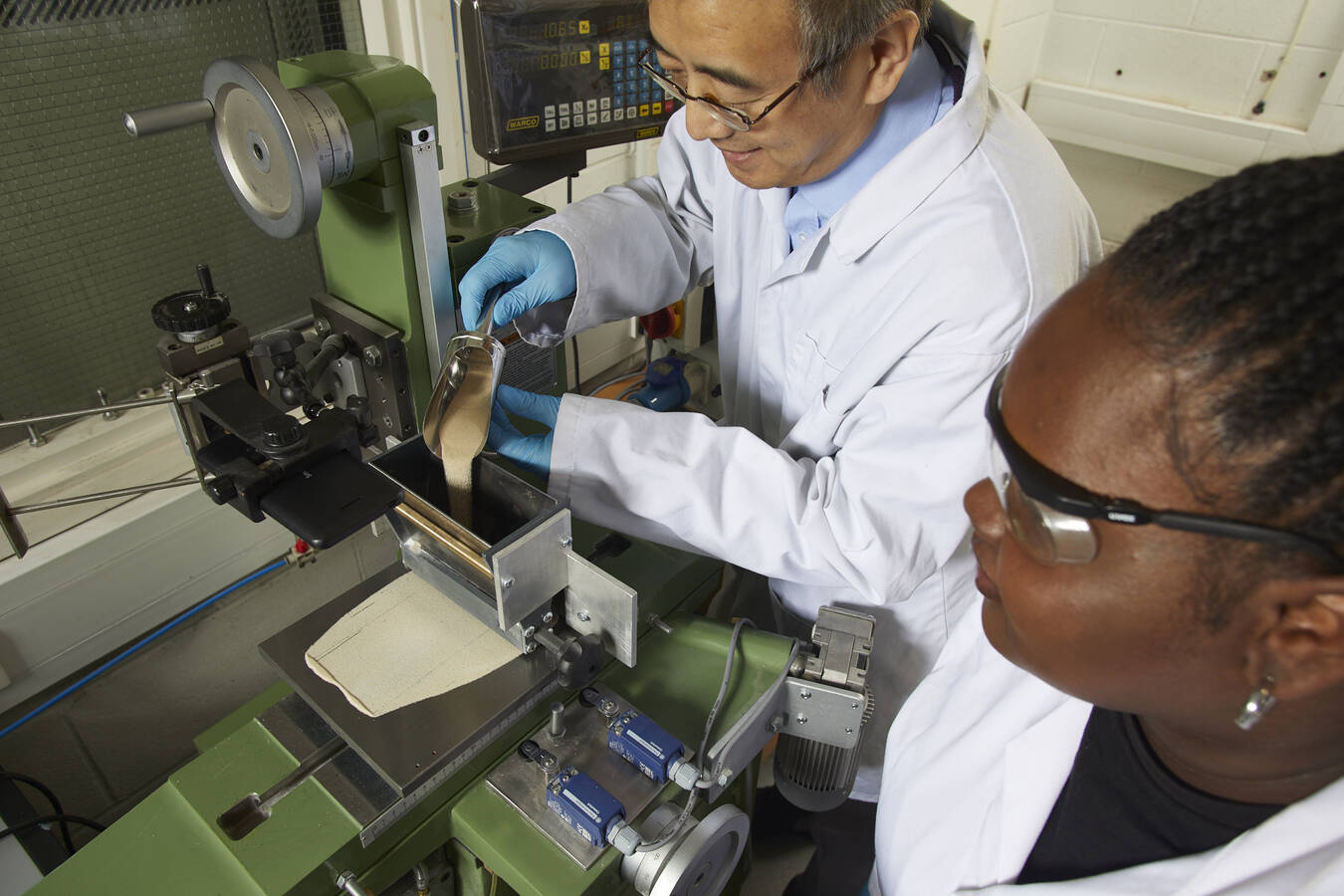

Simplify grinding, mixing, alloying, homogenising

Planetary Ball Mills are first choice for fast, loss-free fine grinding for efficient sample preparation for analysis. FRITSCH Planetary Ball Mills classic line guarantee safe clamping of the grinding bowls, offer particularly easy, ergonomic operation and fast and easy cleaning. And are characterised by consistent reproducibility and long, reliable service life even under continuous, heavy duty usage.

A final fineness below 1 µm can be achieved and the grinding process can be performed dry, in suspension or in inert gas. In addition to comminution, you can also use the FRITSCH Planetary Mills classic line for mixing and homogenising of emulsions and pastes or for mechanical alloying and activation in material research. Ideal in the areas of Geology, Mineralogy, Ceramics, Chemistry, Biology, Pharmaceuticals, Metallurgy and Material Technology.

Your advantages with the Planetary Mills classic line:

- Fast grinding with up to 800 rpm down to a final fineness < 1 µm

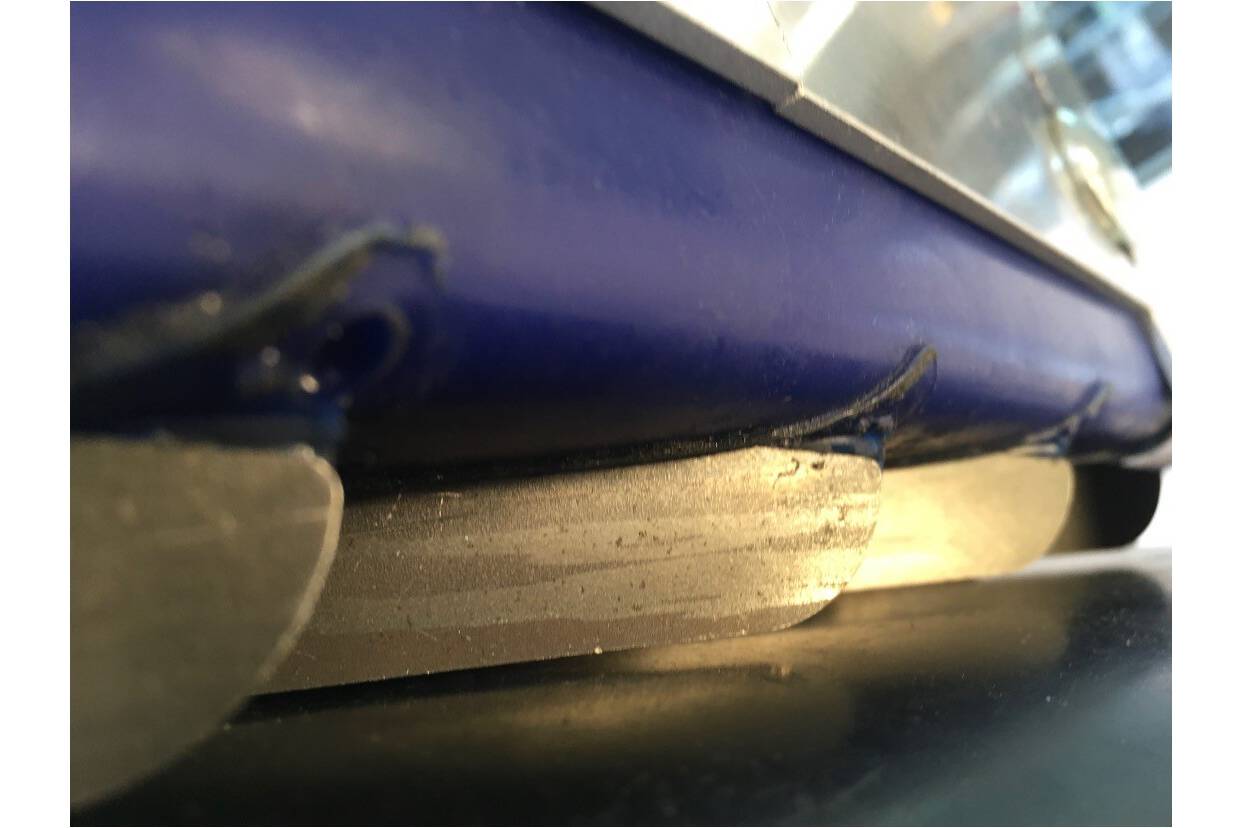

- Safe clamping of the bowls with the Safe-Lock-System

- Simple, ergonomic handling and easy cleaning

- Grinding