Hero@Zero: Masterflex transforms business mode

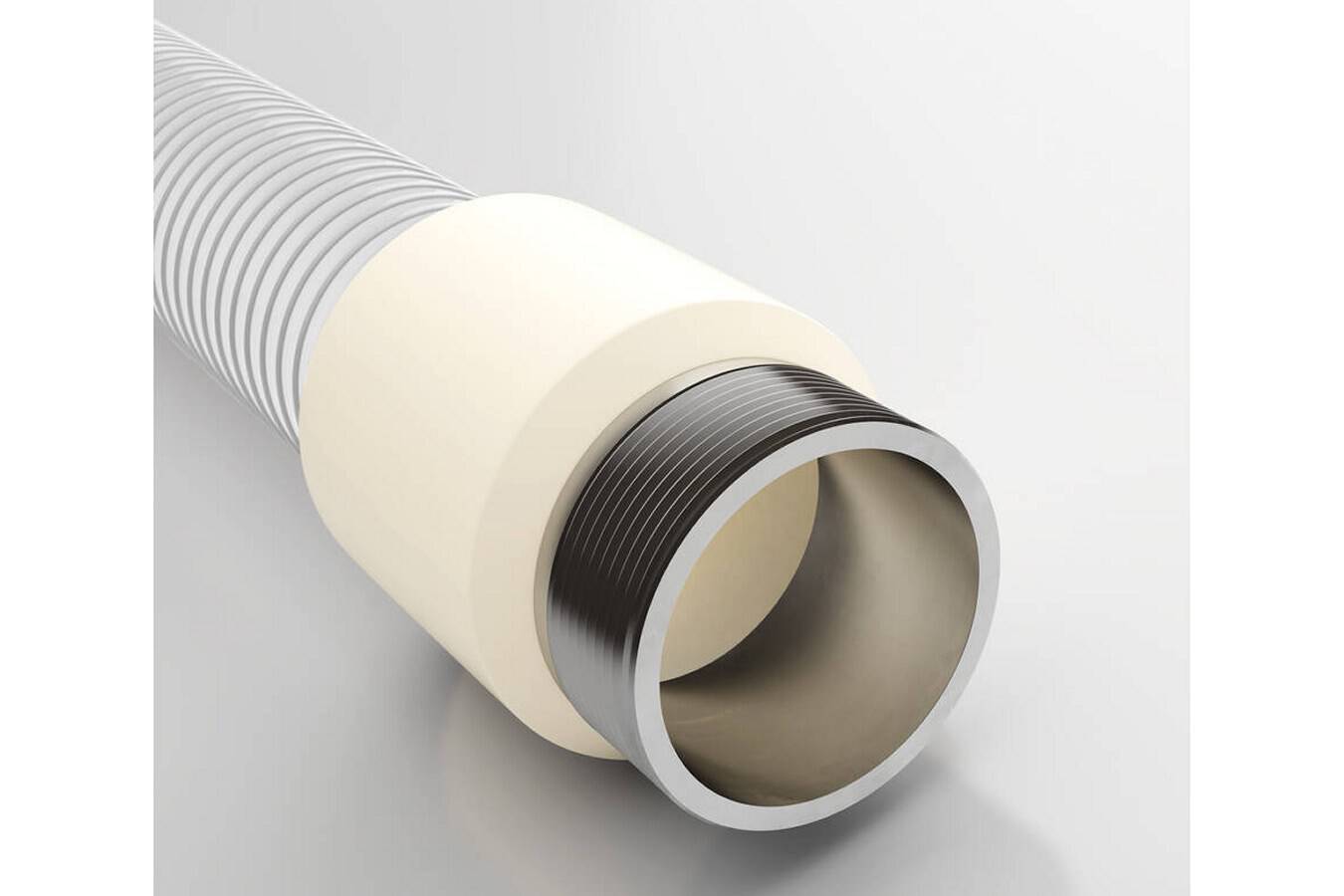

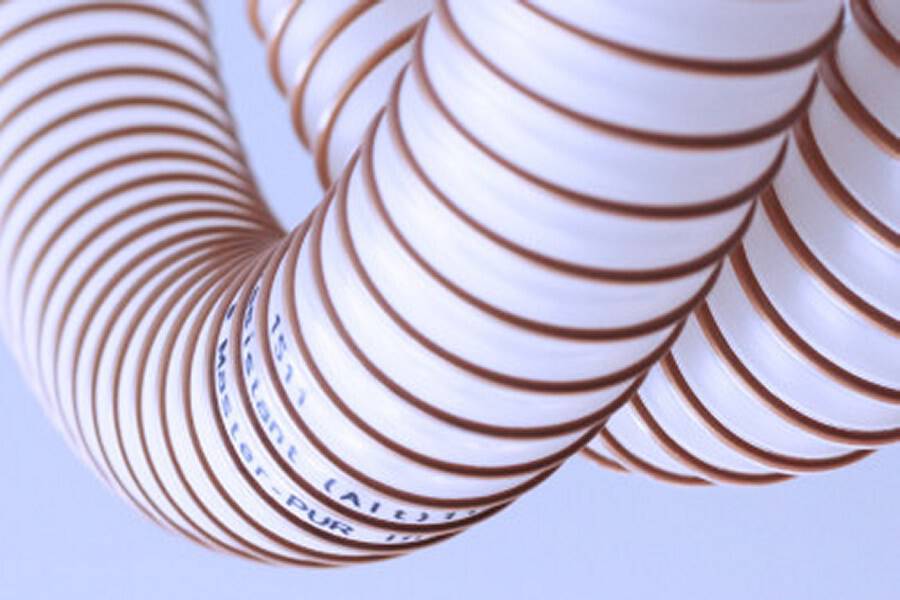

The Masterflex Group is revolutionizing the market for hoses and connecting systems and transforming it into a circular economy.

The Masterflex Group is expanding its product, consulting and solution know-how to include eco-effectiveness, i.e. a circular economy without additional resource consumption. To this end, the current business model will be transformed and expanded in stages up to 2035.

The focus will be on the AMPIUS® digital hose world, which will provide a digital twin of all products and their life cycles to enable a circular economy for hoses and connecting systems.

To this end, today’s consulting and product business will be gradually repositioned by 2035 and expanded to include additional services such as take-back, recycling and eco-certification. The goal is an endless circular economy of plastic hoses.

In doing so, the Masterflex Group, as a leader in its market (”Hero”), is committed to not consuming any additional resources (i.e. ”Zero”).

”With our Hero@Zero strategy, we want to make an economically and ecologically traceable positive contribution for our customers. Our vision is a circular economy for hoses and connection systems without the need for additional resources,” says Dr. Andreas Bastin, CEO of the Masterflex Group.

In addition to operational excellence, digitalization and internationalization, this is another aspect of the Masterflex Group’s transformation into a company that will also be secure and modern in the future.