Screw feeder with ATEX certification and FDA approval

Sinfimasa presents a solution for dosing very fine, explosive bulk solids, in this case active ingredients of medicines. In a practical situation, dosing of 300 litres per hour of micronised bulk product (active ingredients of medicines) was required. As the substance was explosive, a machine with ATEX GAS 1 certification was provided.

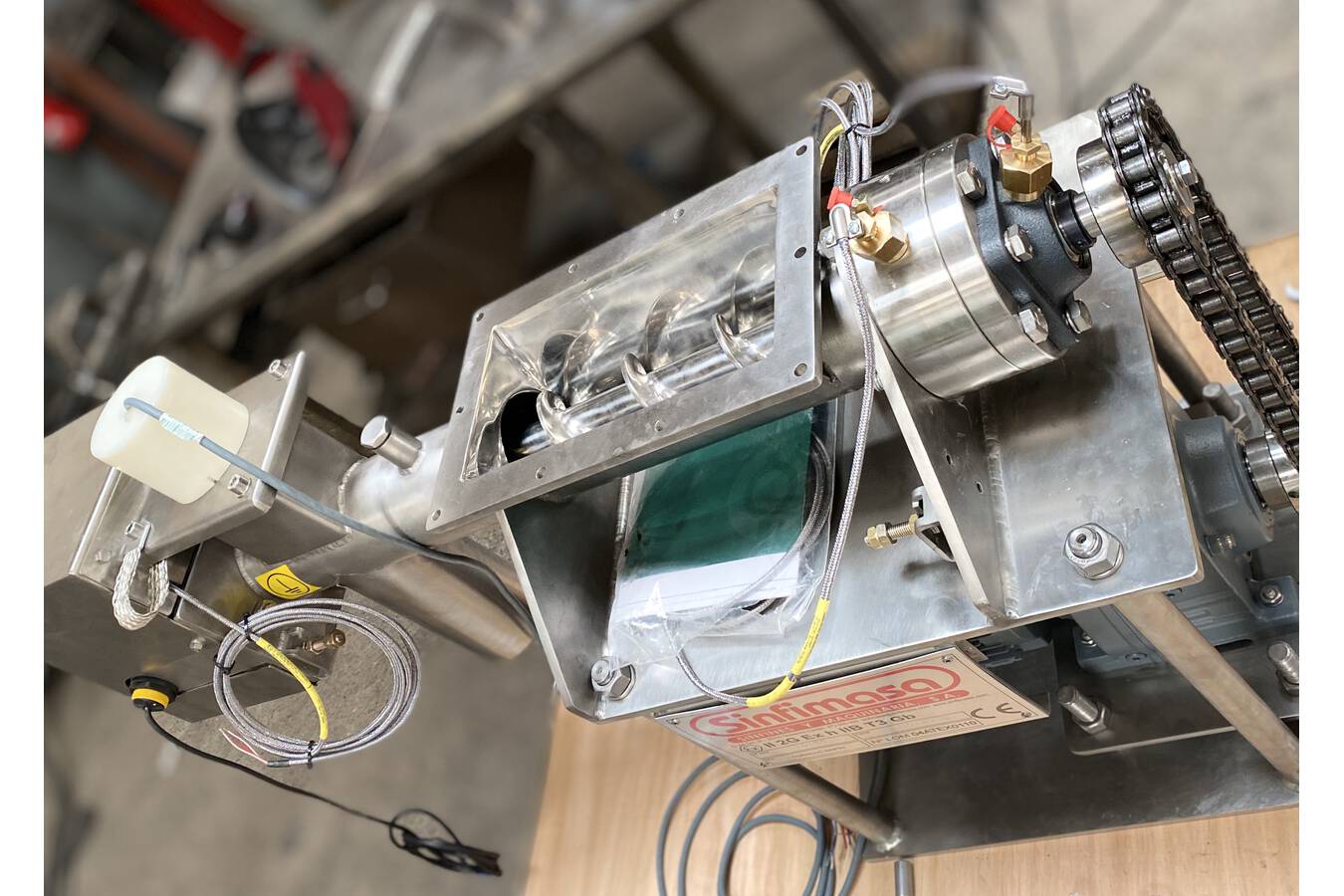

Sinfimasa designed a stainless steel 316 tube screw feeder, suitable for ATEX zone 1 (2G). A screw of 70 mm and a tube of 80 mm were chosen, so that there is a large clearance. The screw is driven by a 0.75 kW ATEX certified motor gearbox.

All parts that may come into contact with the product, such as seals, plastics, grease, etc., are FDA-compliant thanks to the hygienic, easy-to-clean design.

The product itself is a sticky product, so the tube is manufactured with a glossy polished (g220) inner surface and an industrial satin matt outer surface.

In accordance with directive 2014/34/EU, equipment and protective systems intended for use in potentially explosive atmospheres must be designed with a view to integrating explosion protection. These