Efficient Mixing Technology

PTS Batchmixer The mixing process is an important process in the handling of bulk materials, especially in the pharmaceutical sector, where highly active substances must be mixed as carefully as possible and free of contamination. Choosing the appropriate mixing technology is therefore of paramount importance.

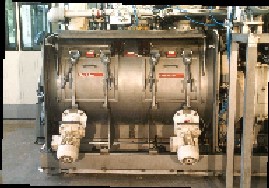

The Batchmixer, developed by Dec, is the only mixing system that has no mechanical or moving parts and achieves sophisticated mixing processes.

The system is based on the PTS - Technology (Powder Transfer System) and uses vacuum and pressure. A homogeneous mixture by circulation is obtained in a short time. The powder to be mixed, even hygroscopic or explosive substances, is sucked in, circulated for a while in the container and after the mixing process completely emptied. Due to the dense phase conveying with reduced flow velocity the particles remain largely intact.

The closed system provides a very high degree of containment.

Academic studies have shown that the