Blender design compliant to EHEDG

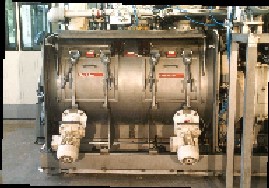

Thrust blenders are the most suitable for gentle mixing of products with broad particle size distribution. For a functional-drink-application a ribbon type blender with 3000 litres useful volume was built.

The blender has a single shaft. The mixing tools are ribbons, which are arranged screw-like at two circumferences. The inner ribbon with the smaller diameter promotes the product from the centre outward and the outer ribbon again inward. Pushing the ribbons through the bulk product provides the mixing.

For application in the foodstuffs industry an EHEDG compliant design is used. The materials of construction were carefully selected and high quality surfaces were realized; furthermore, bolted connections were avoided as far as possible. Special attention was paid to dead-space-free constructions at the discharge, where a metallic sealing was implemented. Since the blender is wet cleaned, it is provided with particularly large openings, which improve the accessibility