Which bulk material conveyor for which situation?

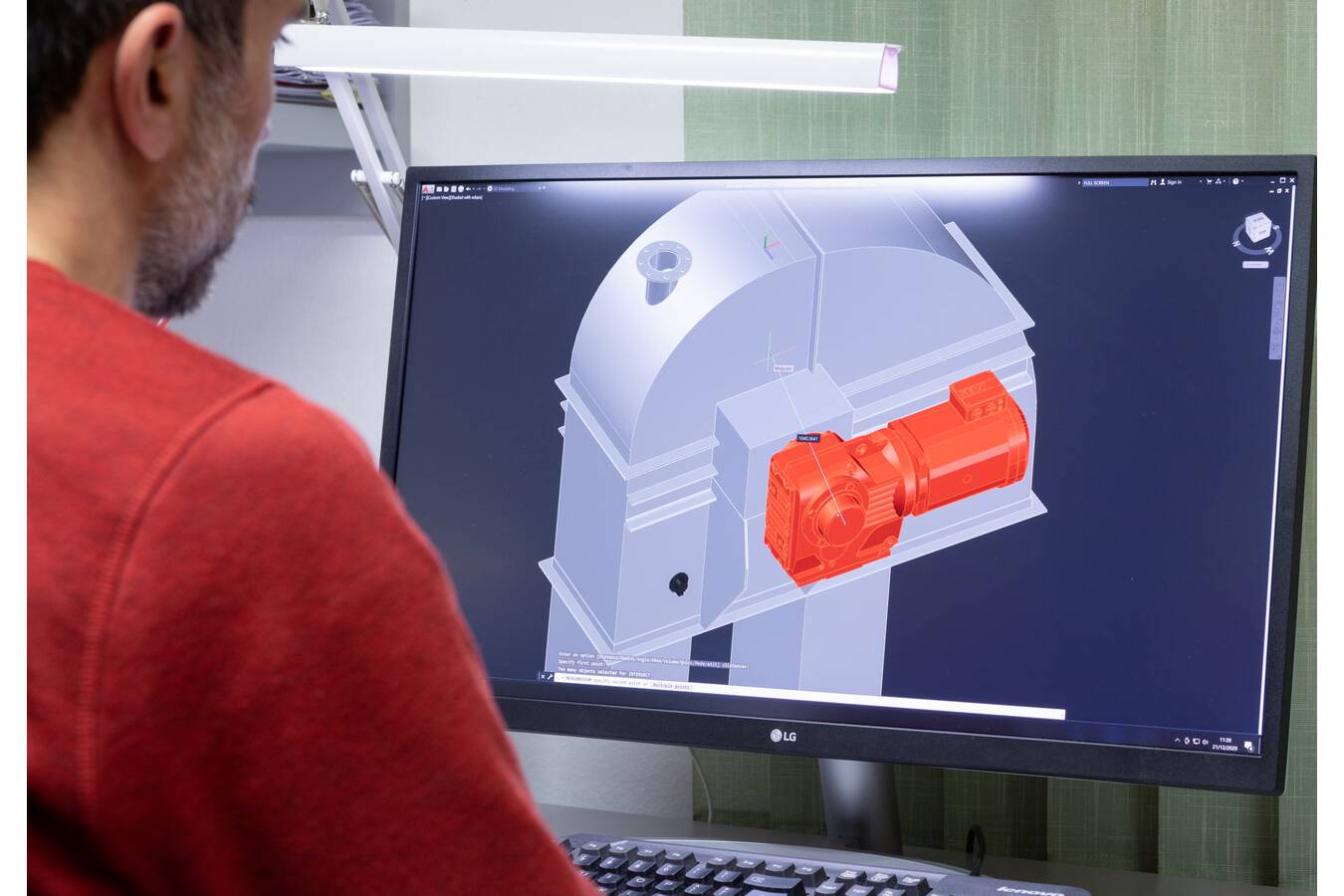

Chain and screw conveyors versus belt conveyors. Sinfimasa manufactures chain and screw conveyors specifically for each customer and project. Which bulk material conveyor for which situation?

Chain and screw conveyors versus belt conveyors

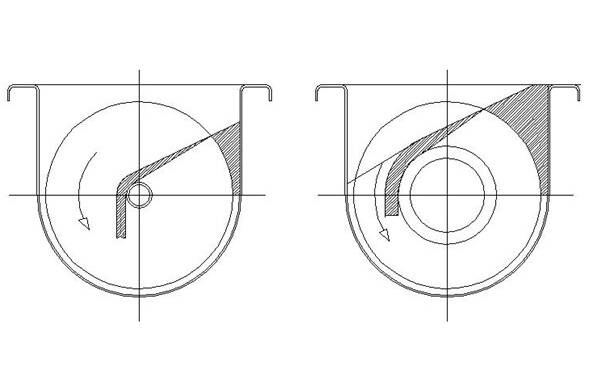

There are several alternatives for conveying bulk materials. The most important of these are screw conveyors, belt conveyors and chain conveyors. Conveyors for bulk material should always be tailored to the situation: the movement path and the characteristics of the specific bulk material. Which type of conveyor is best for each situation?

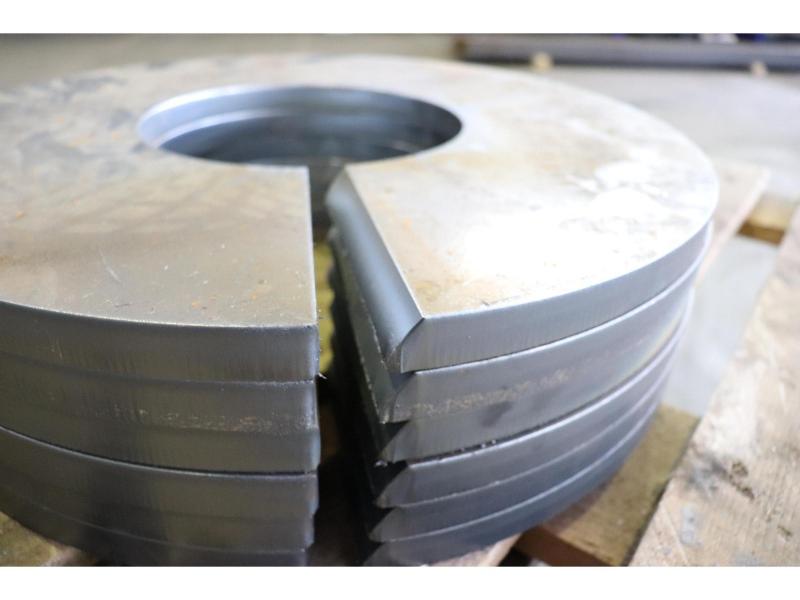

At Sinfimasa, we always say that the most important factor determining the choice of conveyor type is the product to be transported. Before the engineer defines the system, the properties of the product and conditions must be characterised. To mention are: the bulk density, grain size, abrasiveness, corrosivity, the temperature at which it will be transported, the power required, the degree of clumping, hygroscopicity, etc... Depending on the product and the configuration of the process or plant, one device will be better than