Individual consulting and systems engineering. Always ahead in quality with NOLL.

35 years experience and expertise in fine particle technology combined with creativity and spirit of invention: NOLL is the specialist for dry processing and refinement of materials in the ultra-fine range. Like no other, the Noll Company her practical experience in powder processing and systems engineering with sharp analysis and technological ingenuity.

Both NOLL company divisions develop economical solutions in fine particle technology, ahead of time and competition. At ULF NOLL Service & Beratung, clients benefit from personal consulting and individual support in product development, R & D and testing and toll grinding projects. Aufbereitungstechnologie NOLL GmbH stands for construction engineering and processing technology, for mills and classifiers strong in product optimization especially in the micron and nano range <2 µm - 20 µm.

ULF NOLL Service & Beratung

Finest solutions in fine particle technology.

Ulf Noll is the top contact for all those who seek individual consulting in powder processing and personal support to pursue innovative directions in dry processing technology. Clients benefit from customized project management, from Ulf Noll’s striking spirit of invention and his 35 years experience and expertise in fine particle technology.

ULF NOLL Service & Beratung works for market leaders in a great variety of sectors: food, automotive, coating & paint, ceramics, cosmetics, pharmaceutics, dental products, medical and environmental technology …giving them and their products new momentum to set quality standards in their markets through smart processing in the micron and nano range: product development, material optimization and special procedures that go far beyond the ordinary – solutions you will only find at NOLL’s.

Intensive commitment in all phases of cooperation is Ulf Noll’s trademark. Companies profit from his support in their R & D, their practical tests on high-tech equipment and toll grinding projects.

A wide array of services, such as innovative systems engineering and milling equipment, leaves every option open to the clients of ULF NOLL Service & Beratung. Ulf Noll’s core competences include process optimization, reducing wear and tear, minimizing costs, saving energy and raw material, reducing emissions.

Aufbereitungstechnologie NOLL GmbH

Full service in systems engineering & processing technology.

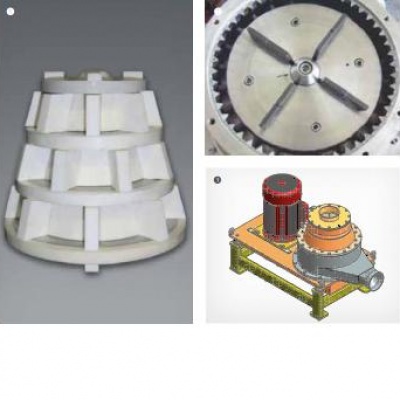

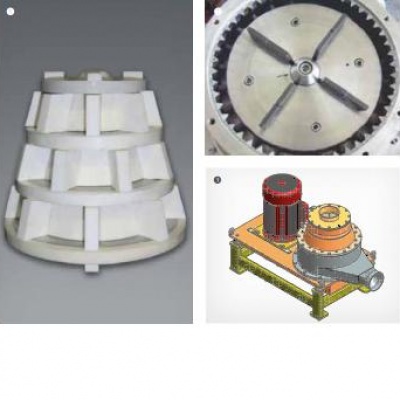

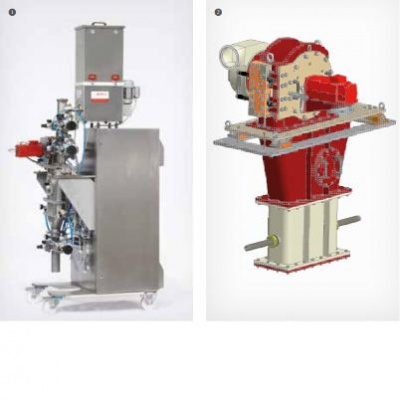

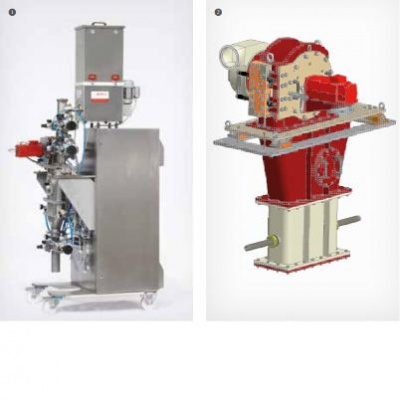

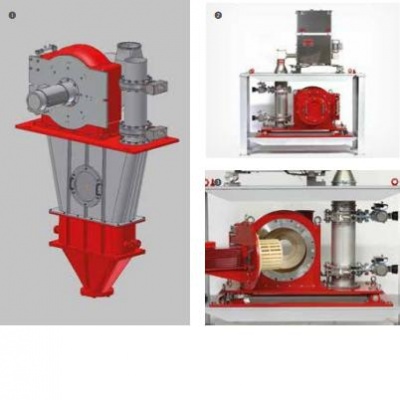

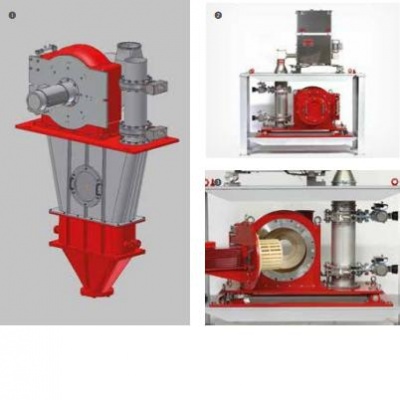

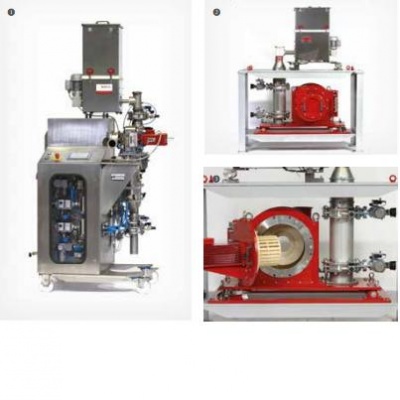

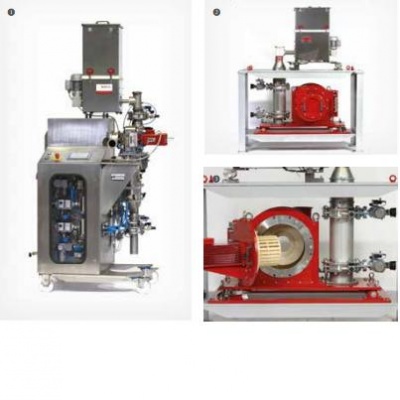

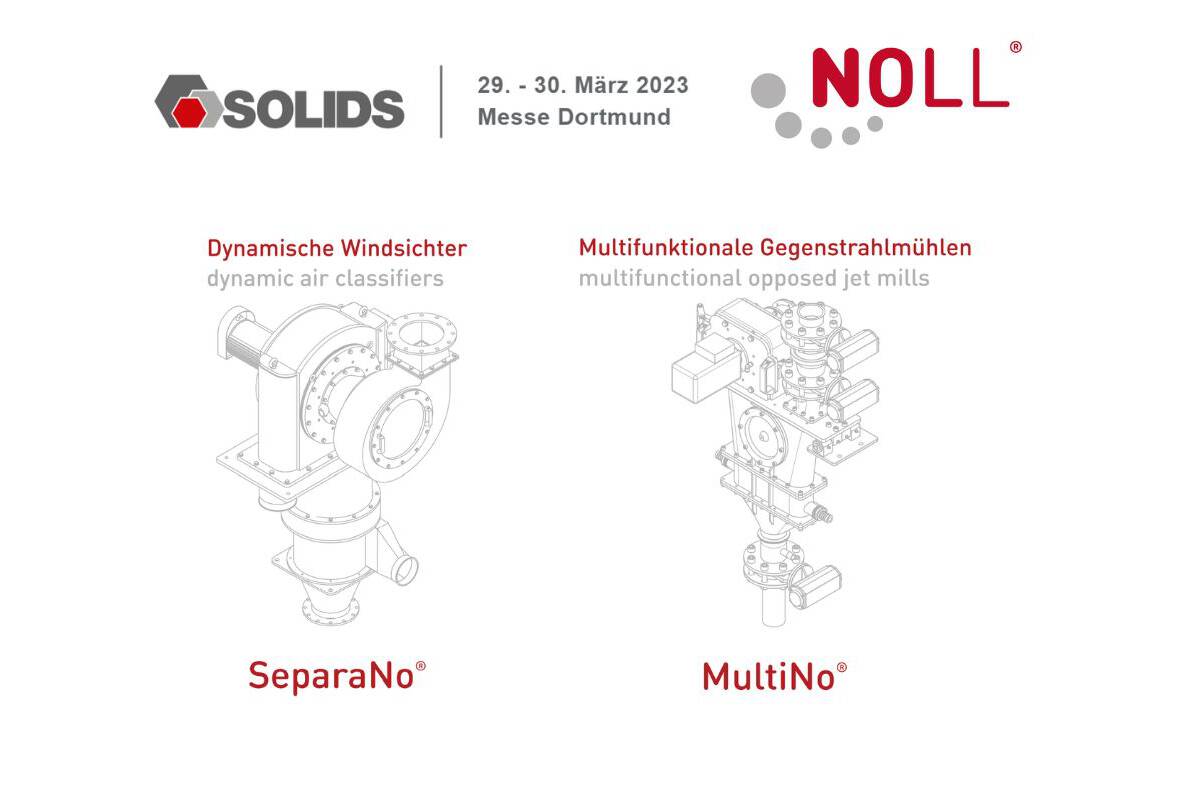

Solutions which surpass standard procedures, smart engineering for the small technical laboratory unit up to large-scale, multifunctional industrial production systems – NOLL has them first. The specialist’s high-tech mills and classifiers are present in dry processing worldwide. NOLL’s latest innovation is compact DemiNo® 3125 L – an impact jet mill without sieve but with rotor and stator – with a patented, new rotor design specially developed for versatile application in the food industry.

NOLL opposed jet mills, impact jet mills and dynamic classifiers provide special and combination processing in a fines particle size range <2 µm to 2000 µm. Their core competences are refinement in the micron and nano range <2 µm - 20 µm, the treatment of abrasive and hard substances up to Mohs hardness 10, as well as efficiently combining several procedures in an online process on multifunctional systems.

Whether clients are interested in individual machines or a complete processing system: NOLL offers the perfect processing solution, individually configured to each application. Smart planning also sets the framework for efficient energy use and the powder processing facility’s profitability. Ulf Noll and his team provide assistance in system design, acquisitions, modification or fine-tuning. With first-class consulting on how a pioneering solution may look.

Categories

Particle size reduction - Crushers, mills -

Air classifiersSeparation, sieving, filtering - Separation -

Air classifiersParticle size reduction - Crushers, mills -

Air jet millsParticle size reduction - Crushers, mills -

Ball millsParticle size reduction - Crushers, mills -

Bar millsParticle size reduction - Crushers, mills -

Barrel millsServices - Design, realisation -

Construction and planningParticle size reduction - Crushers, mills -

Cryogene millsParticle formation - Granulators -

Cutter granulatorsSeparation, sieving, filtering - Dedusting -

Dedusting technologyMixing, blending - Mixers -

DispersionSeparation, sieving, filtering - Dedusting -

Gas cyclonesParticle size reduction - Crushers, mills -

Impact millsParticle size reduction - Crushers, mills -

Jaw crushersParticle size reduction - Crushers, mills -

Knife cuttersParticle size reduction -

Laboratory millsServices - Design, realisation -

Machine and installation buildingServices - Measurement, analyses -

Particle size distribution measurementsMixing, blending - Mixers -

Plough shear mixersSeparation, sieving, filtering - Dedusting - Filters -

Reverse pulse jet cleaned filtersDosing/Weighing - Volumetric feeding -

Rotary feedersDosing/Weighing - Volumetric feeding -

Screw feedersParticle size reduction - Crushers, mills -

Sieve millsParticle size reduction - Crushers, mills -

Spiral jet millsSeparation, sieving, filtering - Sieving, sieves -

Vibratory sievesParticle size reduction - Crushers, mills -

Zigzag classifiers